Understanding the Wiring Diagram For Air Compressor Motor is crucial for anyone who owns, maintains, or repairs an air compressor. This diagram serves as a blueprint, outlining how the electrical components of your compressor motor are interconnected. Whether you're troubleshooting a faulty unit or installing a new motor, having a clear grasp of the Wiring Diagram For Air Compressor Motor can save you time, prevent costly mistakes, and ensure safe operation.

What is a Wiring Diagram For Air Compressor Motor?

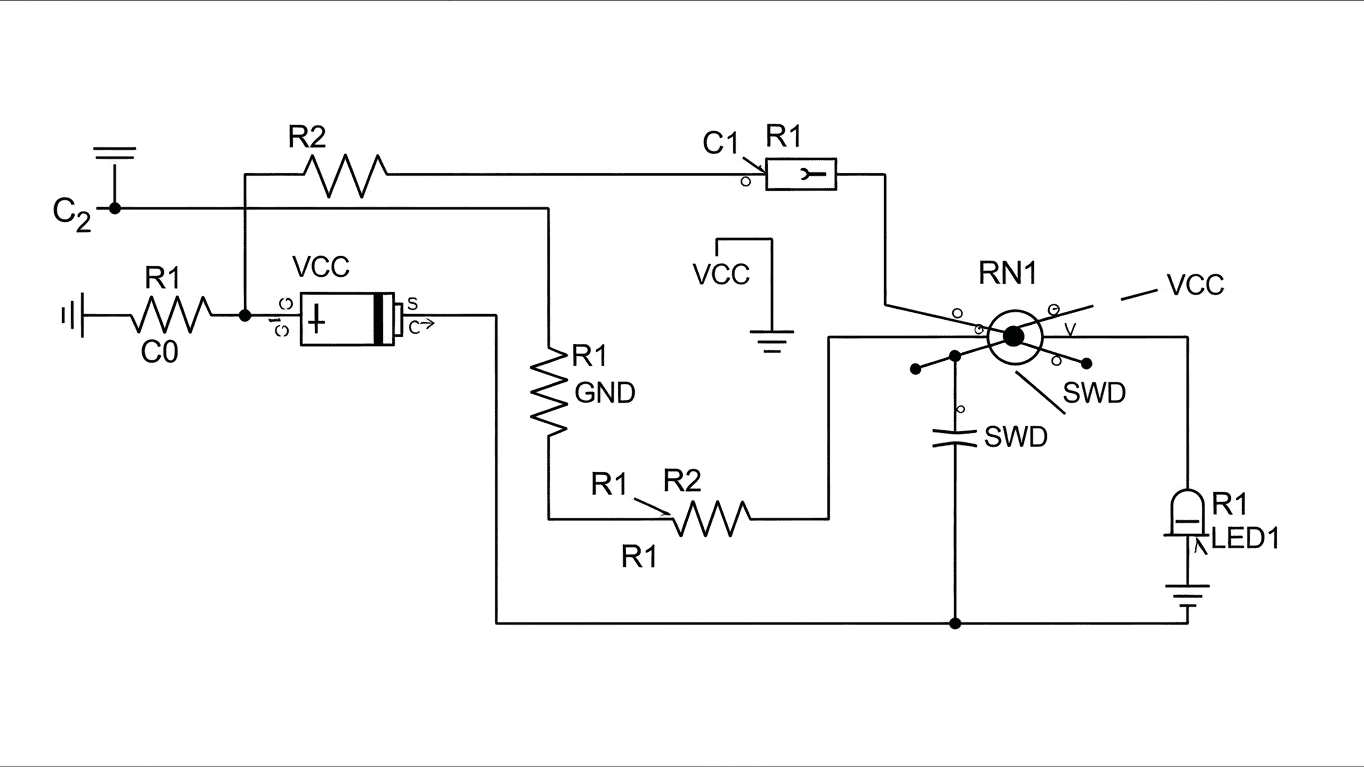

A Wiring Diagram For Air Compressor Motor is a visual representation of the electrical pathways and connections within an air compressor's motor system. It's essentially a map that shows you where each wire goes, what components it connects to, and how they interact to power the motor. This includes information on power supply, switches, capacitors, thermal overload protectors, and the motor windings themselves. Without this diagram, diagnosing electrical issues can be like trying to navigate a maze blindfolded.

These diagrams are indispensable tools for both DIY enthusiasts and professional technicians. They are used for a variety of purposes, including:

- Initial setup and installation of a new motor.

- Troubleshooting and diagnosing electrical problems, such as a motor not starting or running intermittently.

- Performing repairs or replacing faulty electrical components.

- Ensuring proper wiring configurations for different voltage or phase requirements.

- Understanding the safety features built into the motor's electrical circuit.

The importance of consulting the correct Wiring Diagram For Air Compressor Motor cannot be overstated, as incorrect wiring can lead to motor damage, fire hazards, or electric shock.

Wiring diagrams can vary significantly depending on the type of compressor motor, its horsepower, voltage, and whether it's single-phase or three-phase. A simple single-phase motor might have a straightforward diagram, while a more complex three-phase setup will feature more intricate connections. Here's a simplified look at common components you'll find:

| Component | Function |

|---|---|

| Power Input | Where electricity enters the circuit. |

| On/Off Switch | Controls the flow of electricity to the motor. |

| Capacitor (Start/Run) | Assists in starting the motor and/or maintaining its efficient operation. |

| Thermal Overload Protector | Shuts off the motor if it overheats to prevent damage. |

| Motor Windings | The coils of wire that generate the magnetic field to rotate the motor. |

By carefully following the lines and symbols on the Wiring Diagram For Air Compressor Motor, you can trace the flow of electricity and identify potential points of failure. It's always best to have the specific diagram for your compressor model readily available when working on its electrical system.

To ensure you are equipped with the most accurate and reliable information for your specific air compressor motor, please refer to the detailed diagrams provided in your air compressor's owner's manual or the technical documentation accompanying the motor itself.