Understanding the Wiring Diagram For Air Compressor Pressure Switch is crucial for anyone who owns or maintains an air compressor. This diagram acts as a roadmap, guiding you through the electrical connections that control the compressor's operation based on air pressure. Whether you're troubleshooting a faulty switch or installing a new one, having a clear grasp of the Wiring Diagram For Air Compressor Pressure Switch ensures safe and effective repairs.

What is an Air Compressor Pressure Switch Wiring Diagram and How Is It Used?

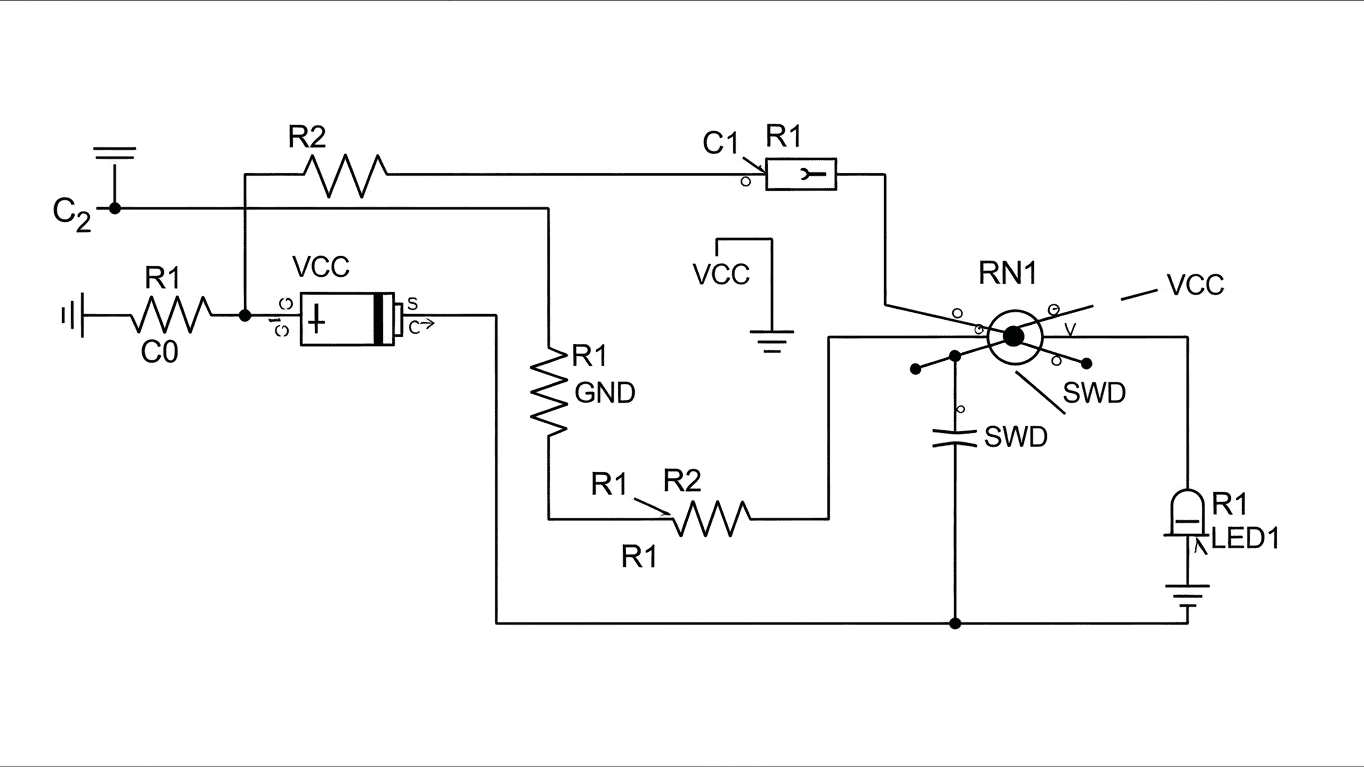

A Wiring Diagram For Air Compressor Pressure Switch is essentially a schematic that illustrates the electrical pathways and components involved in the pressure control system of an air compressor. It shows how the pressure switch, motor, power source, and any associated relays or capacitors are interconnected. This diagram is vital because it allows technicians and DIY enthusiasts to accurately identify each wire, its function, and its connection point. Without this guide, attempting to repair or replace the pressure switch would be a guessing game, leading to potential damage or safety hazards.

The primary function of a pressure switch is to automatically turn the air compressor motor on and off to maintain a desired air pressure range within the tank. When the air pressure drops below a set lower limit, the pressure switch closes its electrical contacts, allowing power to flow to the motor and start the compression process. Once the air pressure reaches a set upper limit, the switch opens its contacts, cutting off power to the motor and stopping compression. This cycle repeats as needed to keep the tank pressurized. The wiring diagram clearly outlines these connections, including:

- The incoming power supply wires.

- The wires connecting to the motor starter or capacitor.

- The connections for any auxiliary devices, such as a check valve unloader.

The accuracy and clarity of a Wiring Diagram For Air Compressor Pressure Switch are paramount for ensuring proper functionality, preventing electrical shorts, and protecting the compressor's motor. Different types of compressors, such as single-stage or two-stage units, and varying pressure ranges will have slightly different wiring configurations. Therefore, it's important to always refer to the specific diagram provided by the compressor manufacturer for your particular model. Here's a simplified representation of typical connections:

| Component | Typical Connection Point |

|---|---|

| Power In (Hot) | Terminal L (Line) on Pressure Switch |

| Power In (Neutral) | Motor Terminal |

| Switch Terminal 1 | Motor Terminal |

| Switch Terminal 2 | Motor Terminal |

Understanding how to read and interpret this diagram empowers you to perform basic maintenance and repairs yourself, saving time and money. It helps in diagnosing issues like a compressor that won't start, runs continuously, or trips the circuit breaker. By following the lines and symbols on the diagram, you can trace the flow of electricity and pinpoint faulty components or loose connections.

We have compiled a comprehensive resource in the following section that will walk you through the specifics of your Air Compressor Pressure Switch wiring. This resource is designed to be your go-to guide for all your wiring diagram needs.