A Wiring Diagram For Air Ride Suspension is your blueprint for connecting all the electrical components that make your custom air suspension system work. It's an essential document for anyone installing, troubleshooting, or modifying their air ride setup, ensuring everything functions as intended for a smooth and controlled ride.

What is a Wiring Diagram For Air Ride Suspension?

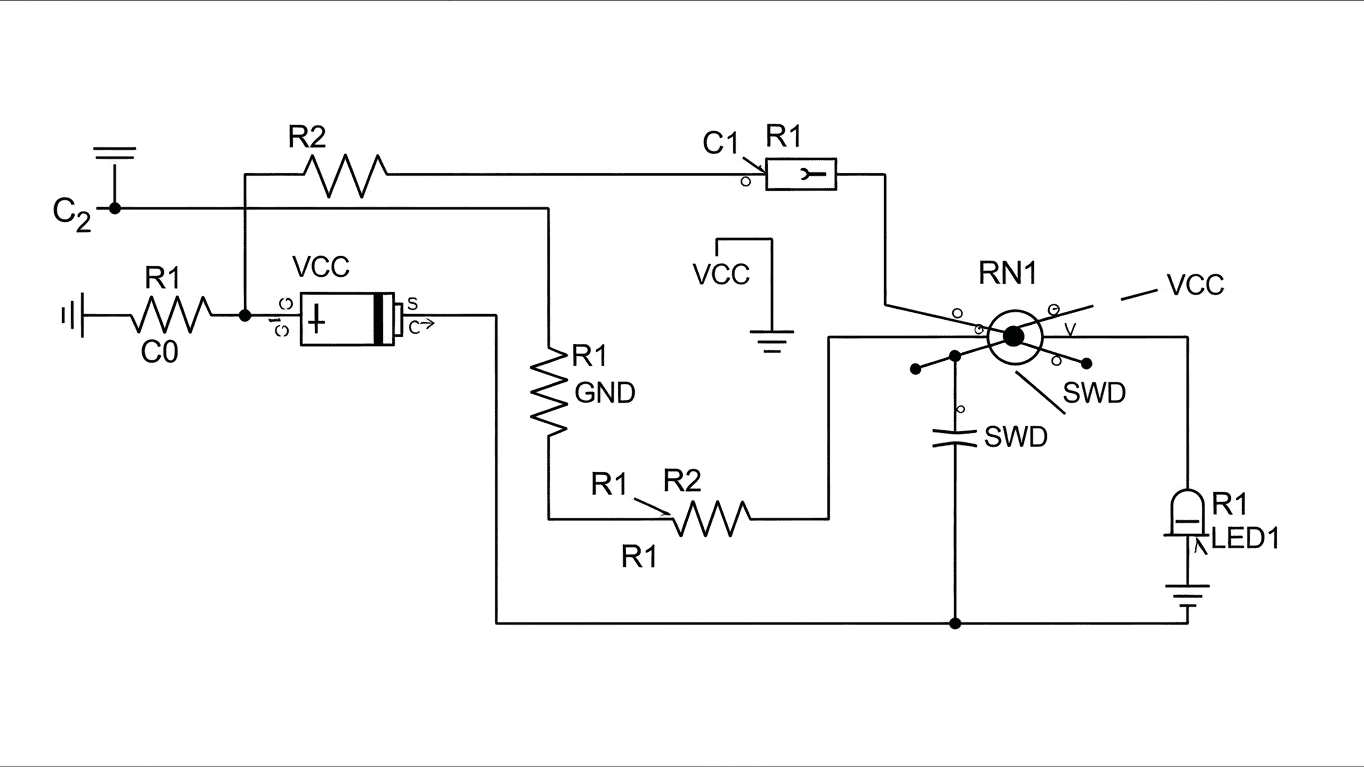

At its core, a Wiring Diagram For Air Ride Suspension is a schematic representation of the electrical pathways within your air suspension system. It visually depicts how various components, such as the air compressor, solenoids, pressure sensors, control switches, and the ECU (if applicable), are interconnected. This diagram is crucial because it clearly outlines the connections for power, ground, and signal wires, allowing for accurate installation and preventing costly mistakes. Without a proper diagram, connecting these components would be guesswork, leading to potential damage or malfunction of the system. The importance of a precise wiring diagram cannot be overstated for a safe and effective air ride installation.

These diagrams are typically provided by the manufacturer of your air suspension kit, but can also be found in specialized automotive repair manuals. They come in various forms, from simple line drawings to more complex schematics that detail specific wire colors, terminal numbers, and fuse ratings. Understanding the symbols and conventions used in the diagram is key. For example, different shapes might represent different components:

- Rectangles: Often represent switches or relays.

- Circles: Can indicate sensors or pressure switches.

- Lines: Represent electrical wires.

- Flashes on lines: May signify specific types of connections or wire gauges.

By following the diagram systematically, you can ensure that each wire is connected to its correct destination. This is particularly important for safety features like overload protection for the compressor and proper operation of the height sensors. A well-labeled diagram often includes a legend that explains these symbols, making it accessible even for those with basic electrical knowledge.

The practical application of a Wiring Diagram For Air Ride Suspension becomes evident during installation and troubleshooting. When installing, you'll use the diagram to physically connect each component in the correct sequence. During troubleshooting, if a part of your air suspension isn't working, the diagram is your first point of reference to trace electrical circuits, identify potential breaks, faulty connections, or blown fuses. A typical basic system might involve connections like these:

| Component | Connection Point |

|---|---|

| Air Compressor | Power (fused), Ground, Relay Trigger |

| Solenoid Valves | Power, Ground, Switch/ECU Output |

| Pressure Sensor | Power, Ground, Signal Output to ECU/Gauge |

| Control Switches/Remote | Power, Ground, Signal Outputs to Solenoids/ECU |

This organized approach minimizes diagnostic time and helps pinpoint the exact location of the electrical issue. It’s the roadmap that guides you through the intricacies of the system.

When working with your air ride suspension, always refer to the specific Wiring Diagram For Air Ride Suspension that came with your kit. This is your most reliable source for accurate installation and troubleshooting guidance.