Understanding the Wiring Diagram For Pressure Switch On Air Compressor is crucial for anyone who owns or works with air compressors. This diagram acts as a blueprint, guiding you through the electrical connections that allow your compressor to operate safely and efficiently. Whether you're troubleshooting a problem or performing maintenance, having a clear grasp of this diagram can save you time, money, and prevent potential hazards.

Understanding the Wiring Diagram For Pressure Switch On Air Compressor

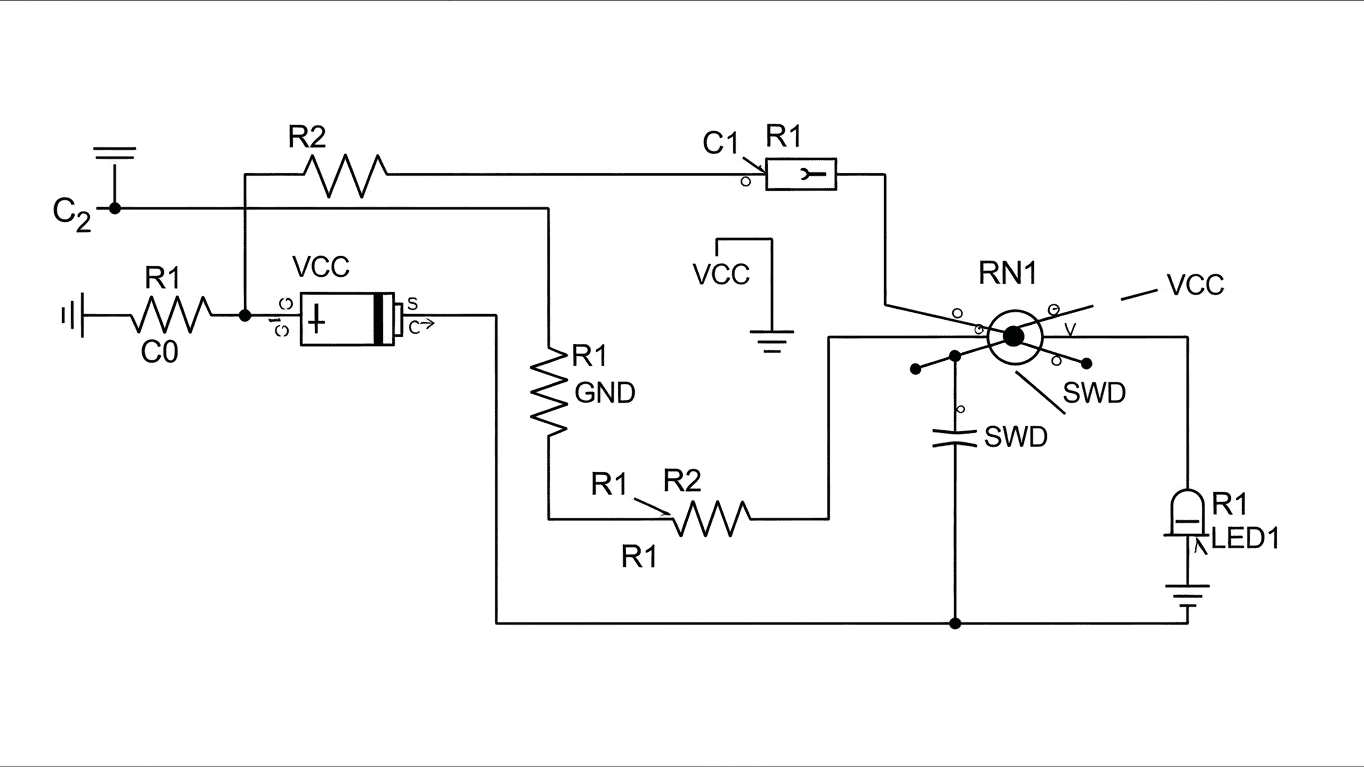

A wiring diagram for a pressure switch on an air compressor is essentially a visual representation of how the electrical components are connected. It shows the path electricity takes from the power source, through the pressure switch, and to the motor that drives the compressor. The pressure switch itself is a vital safety and control device. It monitors the air pressure inside the tank and automatically shuts off the motor when the desired pressure is reached, preventing over-pressurization. Conversely, when the pressure drops below a certain point, the switch allows the motor to restart, ensuring a continuous supply of compressed air.

The complexity of these diagrams can vary depending on the type of air compressor. However, the fundamental principles remain the same. Key components you'll typically find illustrated include:

- Power input (line and neutral wires)

- Pressure switch terminals

- Motor connection points

- Optional components like overload protectors or check valves

The importance of correctly interpreting and following this wiring diagram cannot be overstated. Incorrect wiring can lead to motor damage, electrical shorts, fire hazards, or the compressor failing to operate as intended. It ensures that the pressure switch can accurately control the motor's on and off cycles based on the air pressure within the tank.

Here's a simplified look at the typical flow and components in many diagrams:

| Component | Function |

|---|---|

| Power Source | Provides electricity to the system. |

| Pressure Switch | Monitors tank pressure and controls motor operation. |

| Motor | Drives the compressor pump to generate air. |

When the pressure switch contacts are closed (indicating low pressure), power flows to the motor, starting the compressor. As the pressure builds, the switch will open its contacts at a preset point, cutting power to the motor and stopping it. Some diagrams may also show a secondary set of contacts on the pressure switch, often referred to as a "unloader" circuit, which helps to reduce the load on the motor when it restarts.

For detailed and specific information tailored to your particular air compressor model, it is highly recommended to consult the manufacturer's service manual or the documentation that came with your unit. These sources will provide the most accurate and up-to-date wiring diagram specific to your equipment.