Understanding a wiring diagram for an oil pressure switch is crucial for anyone working on automotive or machinery systems. This diagram serves as a roadmap, detailing how the oil pressure switch, a vital component for engine health, connects to the rest of the electrical system. A clear Wiring Diagram For Oil Pressure Switch ensures proper installation and troubleshooting, ultimately protecting your valuable equipment.

Understanding the Oil Pressure Switch Wiring Diagram

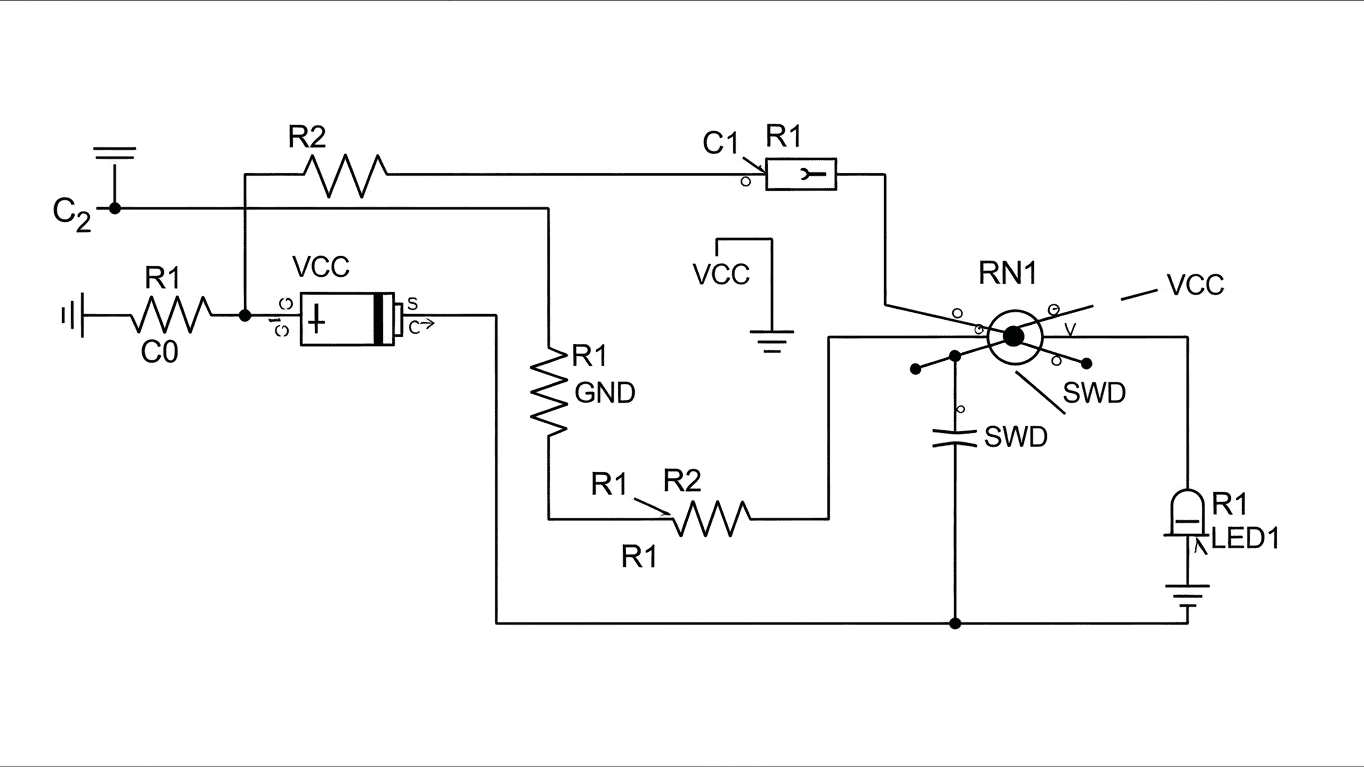

A wiring diagram for an oil pressure switch is essentially a schematic that illustrates the electrical connections involved with this safety device. It shows the switch itself, the wires that connect to it, and where those wires lead within the vehicle or machinery's electrical system. These diagrams are indispensable for mechanics and DIY enthusiasts alike, as they provide a visual guide for installation, repair, and diagnosis.

The primary function of an oil pressure switch is to monitor the oil pressure within an engine. If the pressure drops below a safe operating level, the switch triggers an alert, typically by illuminating a warning light on the dashboard or sounding an audible alarm. The wiring diagram helps to understand how this trigger mechanism works. It outlines the path of the electrical current, showing how the switch acts as a gatekeeper, allowing current to flow to the warning indicator only when oil pressure is insufficient.

Here are some common elements found in an oil pressure switch wiring diagram:

- The Oil Pressure Switch: This is the central component, often depicted as a symbol representing a normally closed (NC) or normally open (NO) switch.

- Power Source: The diagram will indicate the source of electrical power that feeds the switch.

- Warning Indicator: This could be a light bulb symbol or an icon representing an audible alarm.

- Ground Connection: All electrical circuits require a ground connection to complete the path for current.

The complexity of the diagram can vary depending on the system. Some may be very simple, with a direct connection to a warning light. Others might be more intricate, involving relays or integration with other engine control modules. The importance of correctly interpreting this diagram cannot be overstated, as an incorrectly wired oil pressure switch can lead to false alarms, a lack of warning when one is needed, or even damage to the electrical system.

Here's a basic representation of a common single-wire, normally closed (NC) oil pressure switch setup:

| Component | Connection |

| Oil Pressure Switch | Connects to engine block (grounded) |

| Wire from Switch | Connects to the ignition switch/warning light circuit |

| Ignition Switch/Warning Light | Connects to battery power (when ignition is on) |

If you're looking to understand a specific setup or need detailed guidance for your particular vehicle or machine, consult the comprehensive resources provided in the section below this message. They offer in-depth explanations and specific diagrams tailored to various applications.