Understanding a Wiring Diagram For Motor is a crucial skill for anyone working with electrical machinery. Whether you're a hobbyist building a project, a technician performing maintenance, or an engineer designing a new system, a clear comprehension of these diagrams ensures safety, efficiency, and proper functionality. This article will break down what a Wiring Diagram For Motor entails and why it's so indispensable.

What is a Wiring Diagram For Motor and How is It Used?

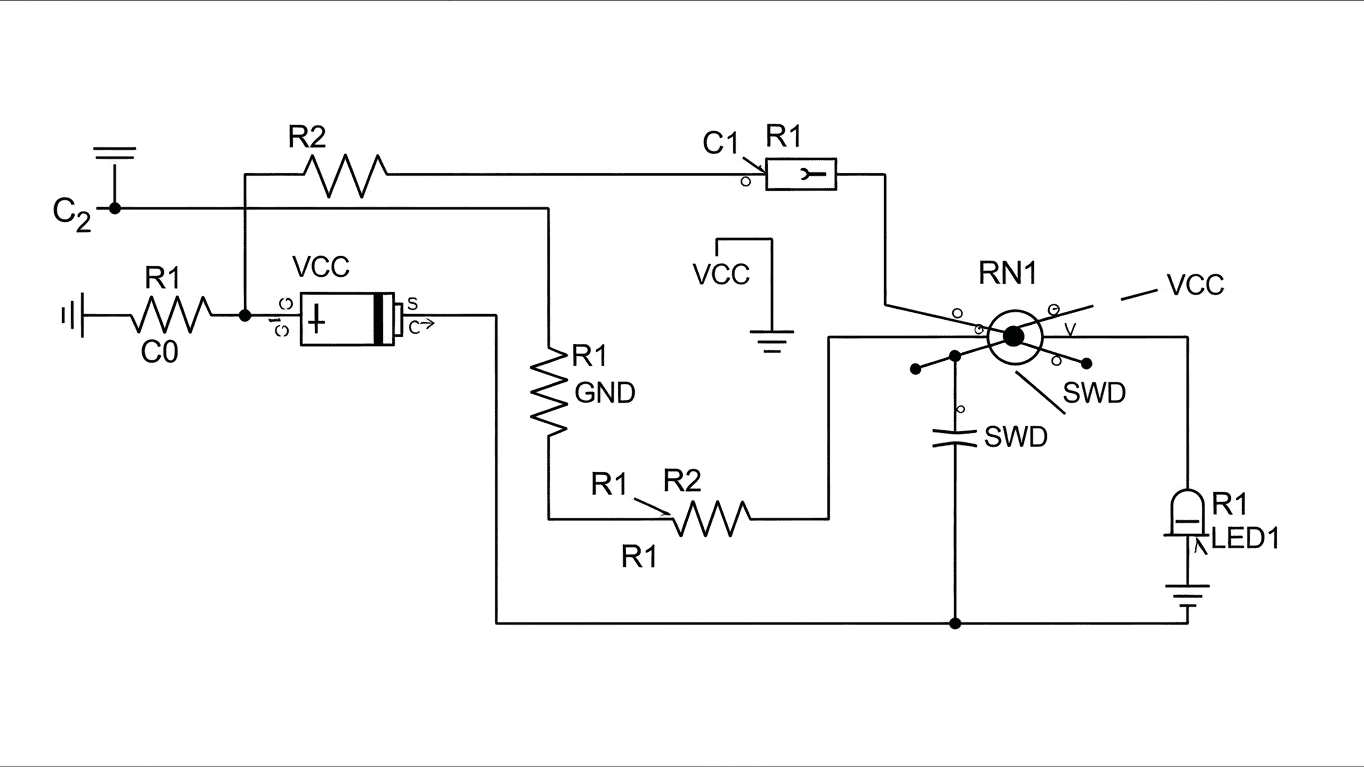

A Wiring Diagram For Motor is a schematic representation that illustrates the electrical connections within a motor circuit. It acts as a blueprint, detailing how components like the motor itself, power sources, switches, relays, overload protection devices, and control circuits are interconnected. These diagrams are not just random lines; they follow specific conventions to convey information precisely. For instance, different symbols represent various electrical components, and lines indicate the paths electricity will flow. The importance of a Wiring Diagram For Motor cannot be overstated; it is the definitive guide for installation, troubleshooting, and repair.

The primary use of a Wiring Diagram For Motor is to guide the assembly and connection of electrical components. Technicians rely on them to ensure that each wire is connected to the correct terminal, preventing short circuits or incorrect operation. They are also invaluable for diagnosing problems. When a motor malfunctions, a technician can follow the diagram step-by-step to pinpoint the source of the issue. This systematic approach saves time and reduces the risk of further damage.

Here are some common elements you'll find in a Wiring Diagram For Motor:

- Power Source (e.g., AC, DC)

- Motor Terminals

- Switches (e.g., on/off, selector)

- Contactors and Relays

- Overload Protection (e.g., thermal overload relays)

- Fuses or Circuit Breakers

- Control Signals

These diagrams can vary in complexity, from simple single-line diagrams for basic applications to detailed multi-line diagrams for more intricate control systems. For example, a simple diagram might show only the power leads and a switch, while a more complex one could detail the winding configurations for different speeds or directions of rotation.

To further illustrate the variation, consider a basic table of common motor types and their general wiring diagram characteristics:

| Motor Type | Typical Wiring Diagram Feature |

|---|---|

| Single-Phase Induction Motor | Often includes a capacitor and centrifugal switch for starting. |

| Three-Phase Induction Motor | Connections for three windings, typically Delta or Wye configurations. |

| DC Motor | Involves connections for armature and field windings, with potential for speed control components. |

As you delve into the world of motor control and maintenance, a reliable source for specific wiring diagrams is paramount. For detailed schematics and expert guidance tailored to your particular motor application, please refer to the manufacturer's manual for your specific motor model.