Understanding the Wiring Diagram For Fuel Gauge is crucial for anyone looking to diagnose or repair their vehicle's fuel system. This essential guide provides a clear overview of what a wiring diagram for a fuel gauge entails, how it functions, and why it's so important for proper vehicle maintenance.

What is a Wiring Diagram For Fuel Gauge and How is it Used?

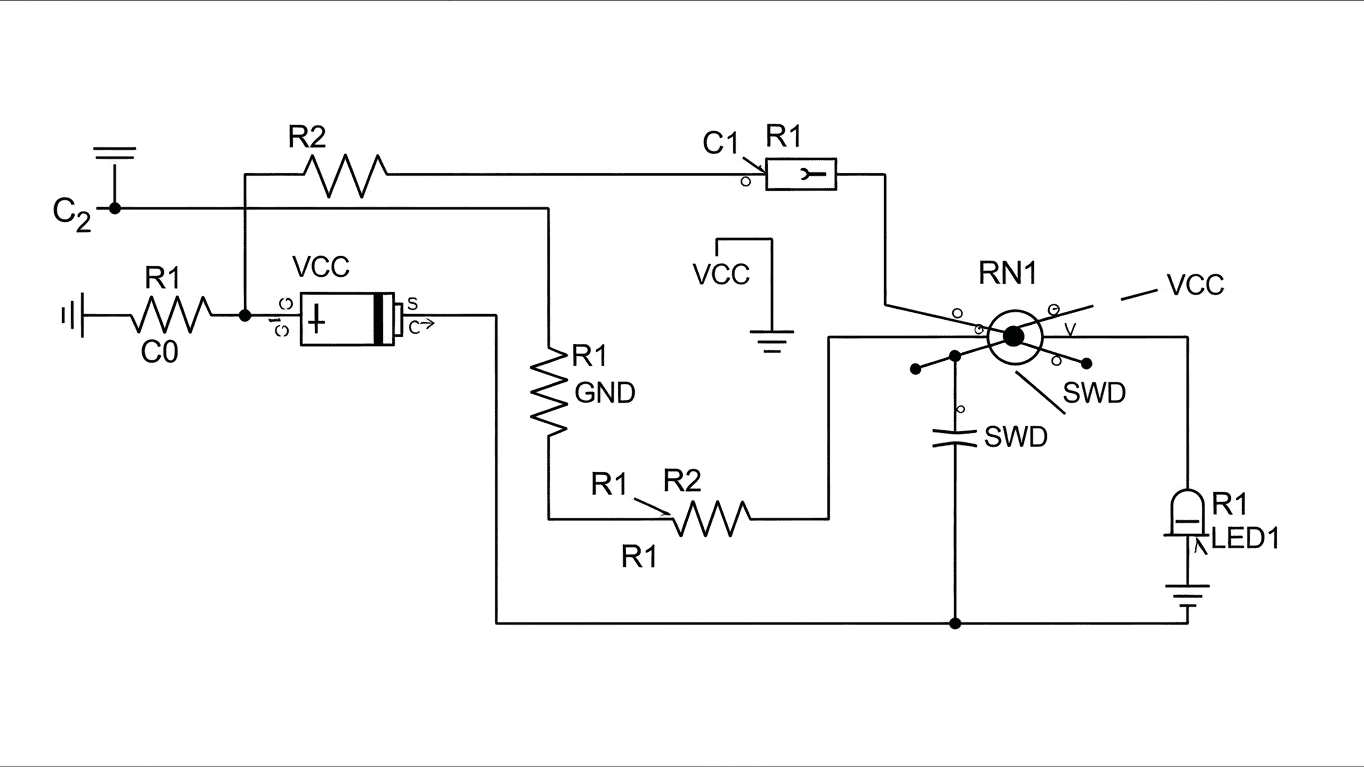

A Wiring Diagram For Fuel Gauge is essentially a schematic or blueprint that illustrates how the electrical components involved in measuring and displaying your fuel level are connected. It shows the pathway of electrical current from the fuel sending unit, located inside your fuel tank, to the fuel gauge itself on your dashboard. Think of it as a roadmap for electricity. This diagram details the type of wires used, their colors, the connectors, and the order in which they should be connected. This visual representation is indispensable for troubleshooting any issues you might encounter with your fuel gauge, whether it's reading incorrectly or not working at all. The ability to read and interpret this diagram is paramount for accurate diagnostics .

The primary function of a Wiring Diagram For Fuel Gauge is to guide technicians and DIY enthusiasts through the intricacies of the fuel level sensing system. Here's a breakdown of its typical components and their roles:

- Fuel Sending Unit: This is the sensor inside the fuel tank. It typically consists of a float connected to a variable resistor. As the fuel level changes, the float moves, altering the resistance.

- Wiring: This connects the sending unit to the gauge. Different colored wires often indicate specific functions (e.g., power, ground, signal).

- Fuel Gauge: This is the display unit on your dashboard that interprets the electrical signal from the sending unit and translates it into a visual representation of the fuel level (e.g., full, empty, or in between).

Using the diagram involves tracing the wires from the sending unit to the gauge, checking for continuity, voltage, and resistance at various points. This systematic approach helps pinpoint faulty components or loose connections. For instance, a common troubleshooting process might involve these steps:

- Inspect the wiring for any visible damage.

- Test for power and ground at the fuel gauge.

- Disconnect the sending unit and manually alter its resistance to see if the gauge responds correctly.

- Measure the resistance of the sending unit itself at different fuel levels.

| Component | Typical Function |

|---|---|

| Sending Unit | Measures fuel level via variable resistance |

| Gauge | Displays fuel level based on electrical signal |

| Wiring Harness | Transmits electrical signals between components |

Without a clear Wiring Diagram For Fuel Gauge, diagnosing problems could become a frustrating and time-consuming guessing game. It provides the necessary context to understand how the system is supposed to work, making it significantly easier to identify what's going wrong.

To effectively troubleshoot your fuel gauge system, it is highly recommended to refer to the specific Wiring Diagram For Fuel Gauge for your vehicle's make, model, and year. This detailed resource is your best guide.