Understanding the inner workings of your vehicle's ignition system is crucial for smooth operation and efficient performance. At the heart of this system lies the distributor, and for modern vehicles, an electronic distributor plays a vital role. A Wiring Diagram For Electronic Distributor serves as a roadmap, illustrating how all the electrical components connect to ensure the spark plugs fire at precisely the right moment. This guide will demystify the wiring diagram, making it accessible even for those new to automotive electronics.

What is a Wiring Diagram For Electronic Distributor and How is it Used?

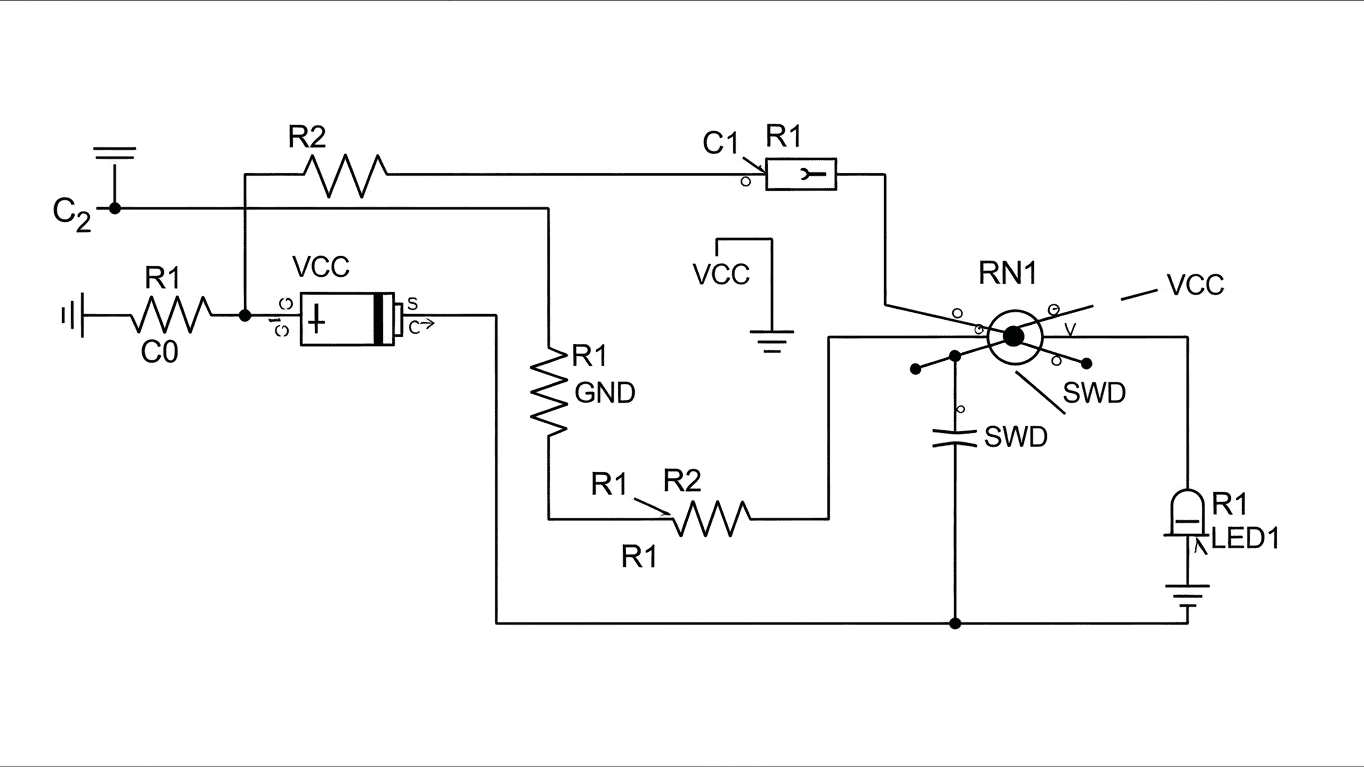

A Wiring Diagram For Electronic Distributor is a schematic representation that details the electrical connections between the various components of an electronic ignition system. Unlike older points-and-condenser systems, electronic distributors utilize solid-state components like Hall effect sensors or magnetic pulse generators to trigger the ignition coil. The diagram shows how power flows from the battery, through fuses and relays, to the distributor's module, and then to the ignition coil and ultimately the spark plugs. Understanding this flow is essential for troubleshooting ignition problems, performing repairs, or even upgrading your ignition system.

The diagram typically uses standard electrical symbols to represent different parts. For instance:

- A line represents a wire or conductor.

- A circle might indicate a terminal or connection point.

- Specific symbols depict components like the distributor module, ignition coil, crankshaft position sensor (if integrated), and the vehicle's computer (ECU).

Mechanics and DIY enthusiasts rely on these diagrams for several key purposes:

- Diagnosis: When an engine misfires or fails to start, the wiring diagram helps trace the electrical path to identify faulty connections, shorts, or open circuits.

- Repair: Replacing a faulty distributor module or ignition coil is made significantly easier with a clear diagram showing where each wire should connect.

- Installation: When installing aftermarket performance distributors or making modifications, the diagram is indispensable for ensuring all connections are correct.

Here's a simplified look at what you might find in a typical Wiring Diagram For Electronic Distributor:

| Component | Function | Typical Connections |

|---|---|---|

| Distributor Module | Controls spark timing and firing order. | Battery (+), Ignition Switch (ACC/RUN), Ground, Ignition Coil (+), Trigger Signal from Sensor |

| Ignition Coil | Steps up battery voltage to a high voltage for spark. | Distributor Module (+), Battery (+), Ground |

| Trigger Sensor (e.g., Hall Effect) | Sends a signal to the module to initiate spark. | Distributor Module (Signal Wire), Ground, (Sometimes powers from module or ECU) |

By carefully examining the lines and symbols, you can follow the electrical journey from power source to spark. The color-coding of wires, often indicated in the diagram, is also a critical piece of information for accurate connections. A comprehensive Wiring Diagram For Electronic Distributor will also often include voltage drop charts and troubleshooting steps specific to the vehicle model.

To effectively diagnose and repair your vehicle's ignition system, refer to the specific Wiring Diagram For Electronic Distributor for your car's make, model, and year. This detailed schematic will be your most valuable tool in ensuring your engine receives the spark it needs to run reliably.