Understanding the intricate workings of your equipment is crucial for efficient operation and maintenance. A Wiring Diagram For Compressor serves as the blueprint for connecting all the electrical components of a compressor. This guide will demystify what a wiring diagram is and why it's indispensable for anyone dealing with compressor systems.

Understanding Your Compressor's Electrical Heartbeat

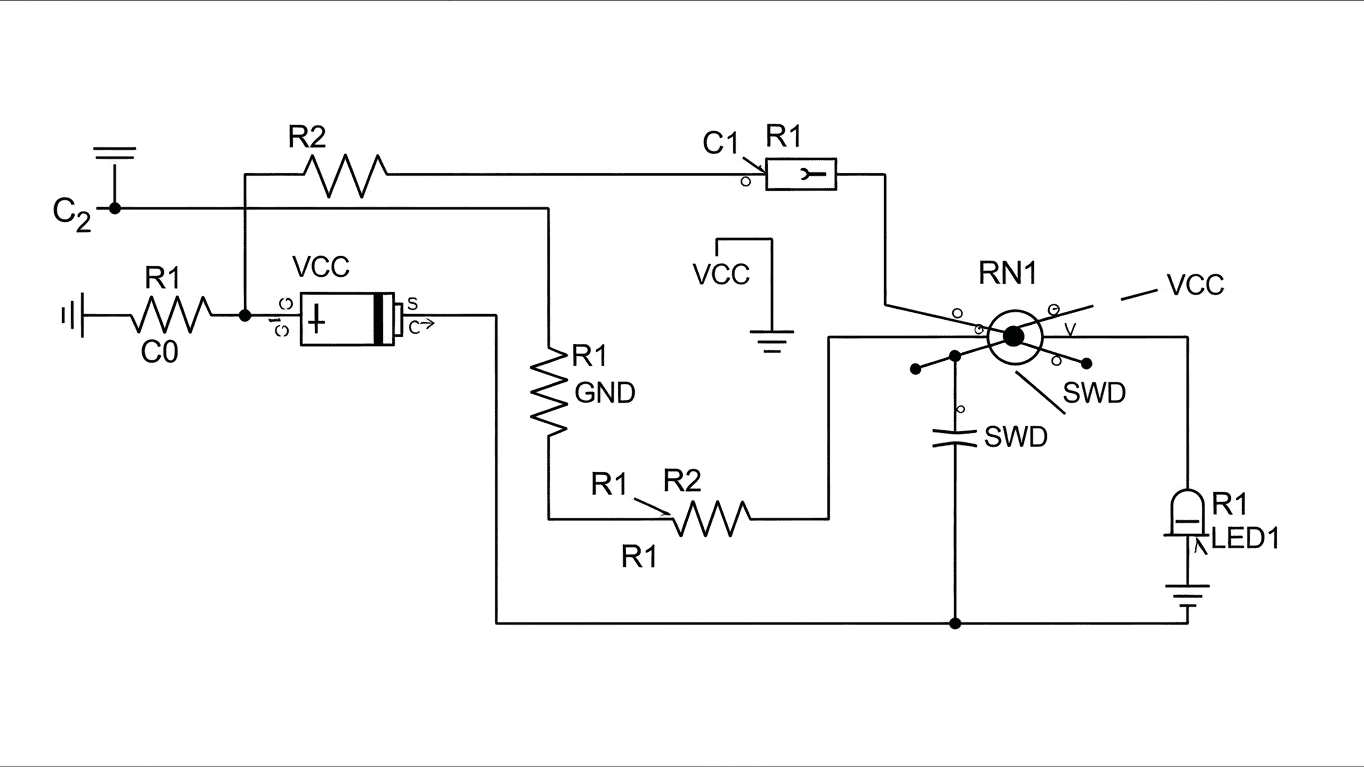

A Wiring Diagram For Compressor is essentially a visual representation of how the electrical components of a compressor are interconnected. It shows the flow of electricity from the power source to various parts like the motor, switches, control panels, and safety devices. Think of it as a roadmap for electricity, detailing every wire, connection point, and component's function. Technicians and engineers use these diagrams extensively for troubleshooting, repairs, and even initial setup. Having a clear and accurate wiring diagram is paramount for ensuring the safe and effective operation of any compressor.

These diagrams are not just random lines and symbols; they follow standardized conventions. For instance, different symbols represent different electrical components:

- A circle with an 'M' inside often signifies a motor.

- A diagonal line across a circle might represent a switch.

- Rectangles can depict various control modules or relays.

The lines themselves illustrate the wiring, indicating connections and pathways. They can also show the gauge of the wire and its intended purpose. A well-designed diagram will also include a legend that explains the meaning of each symbol used. Essentially, a Wiring Diagram For Compressor breaks down a complex electrical system into understandable parts.

The practical applications of a Wiring Diagram For Compressor are numerous. During installation, it ensures all connections are made correctly, preventing potential damage or safety hazards. When a compressor malfunctions, the diagram becomes an invaluable troubleshooting tool. By following the diagram, a technician can systematically check each component and connection to pinpoint the source of the problem. This methodical approach saves time and reduces the risk of further damage. For routine maintenance, it helps in understanding the function of different parts and ensuring they are operating within their designed parameters. Consider these common scenarios:

- Motor Won't Start: The diagram helps trace power to the motor, check safety interlocks, and verify control circuit functionality.

- Overheating Issues: It allows inspection of the motor's overload protection and ensures correct wiring for cooling fans, if applicable.

- Unusual Noises: While not directly electrical, wiring issues can sometimes manifest as unusual electrical stress on components, leading to noise. The diagram helps rule out electrical causes.

In summary, a Wiring Diagram For Compressor is an indispensable document for anyone involved with compressor systems. It provides clarity, aids in problem-solving, and ensures safe and efficient operation.

To effectively utilize and understand the nuances of your specific compressor's electrical system, always refer to the detailed wiring diagrams provided by the manufacturer. These diagrams are your primary resource for all electrical maintenance and repair tasks.