Understanding the Wiring Diagram For A One Wire Alternator is crucial for anyone looking to simplify their vehicle's electrical system. This type of alternator is celebrated for its straightforward installation and minimal wiring, making it a popular choice for classic cars, hot rods, and custom builds. While many alternators require multiple connections for excitation, voltage regulation, and battery sensing, a one-wire setup streamlines this process significantly. This article will guide you through the basics of a Wiring Diagram For A One Wire Alternator and its practical applications.

Understanding the Simplicity of a One Wire Alternator

The allure of a one-wire alternator lies in its inherent simplicity. Unlike traditional multi-wire alternators that require connections for battery sensing, field excitation (often through a resistor or indicator light), and output, the one-wire unit integrates these functions internally. This means you only need to concern yourself with a single main output terminal. The alternator itself handles the necessary processes to begin charging the battery once it reaches a certain RPM. This reduction in complexity not only makes installation easier but also reduces the potential for wiring errors.

The core principle behind a one-wire alternator is its self-exciting nature. Here's how it generally works:

- Initial Start: When the engine is first cranked, the alternator is not yet producing a strong enough magnetic field to generate electricity.

- Reaching Operating Speed: As the engine speed increases, the alternator's internal components begin to generate a residual magnetic field.

- Self-Excitation: At a specific RPM (typically around 1200-1500 RPM, depending on the unit), this residual field becomes strong enough for the alternator to self-excite. This means it starts generating its own magnetic field, allowing it to produce voltage and begin charging the battery.

- Voltage Regulation: An internal voltage regulator monitors the system voltage and adjusts the alternator's output to maintain a steady charge.

The importance of understanding this self-exciting mechanism is paramount for proper installation and function. If the engine doesn't reach the required RPM, the alternator will not start charging, leading to a drained battery.

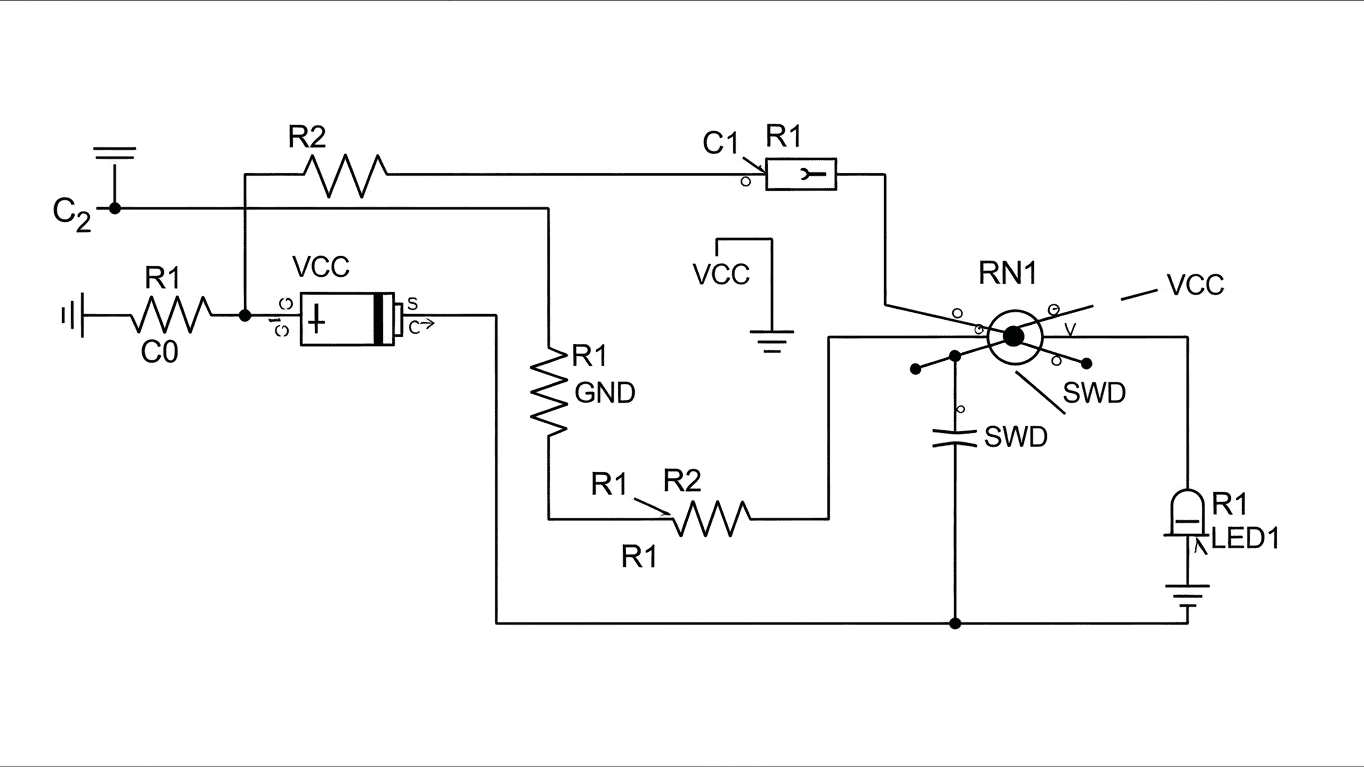

The wiring for a one-wire alternator is remarkably uncomplicated. You'll typically find:

- The Main Output Terminal: This is the single, larger terminal on the alternator. It connects directly to the positive terminal of your battery, often via a substantial gauge wire, sometimes incorporating a fuse or circuit breaker for protection.

- The Alternator Body: The alternator's casing acts as the ground connection. It needs to be securely bolted to the engine block or a properly grounded bracket, ensuring a good electrical connection to the vehicle's chassis.

For clarity, consider this table summarizing the minimal connections:

| Connection Point | Purpose | Wire Gauge Consideration |

|---|---|---|

| Main Output Terminal | To Battery Positive (+) | Heavy gauge (e.g., 8 gauge or larger) |

| Alternator Casing/Mounting Bolts | To Engine Block/Chassis Ground (-) | Ensure clean, solid metal-to-metal contact |

This minimal approach eliminates the need for complex wiring harnesses and external regulators, simplifying troubleshooting and maintenance significantly.

If you are embarking on a project that benefits from simplified wiring, refer to the specific installation instructions provided by the manufacturer of your chosen one-wire alternator. This will ensure you make the correct connections and achieve optimal performance.