Understanding the "Wiring Diagram For 220 Volt Air Compressor" is crucial for any DIY enthusiast or professional who needs to connect or troubleshoot their air compressor. This diagram acts as a blueprint, detailing every wire, connection, and component involved in safely and efficiently powering your 220-volt unit. Whether you're setting up a new compressor or repairing an old one, a clear grasp of this diagram ensures proper installation and prevents potential hazards.

What is a Wiring Diagram For 220 Volt Air Compressor and How Is It Used?

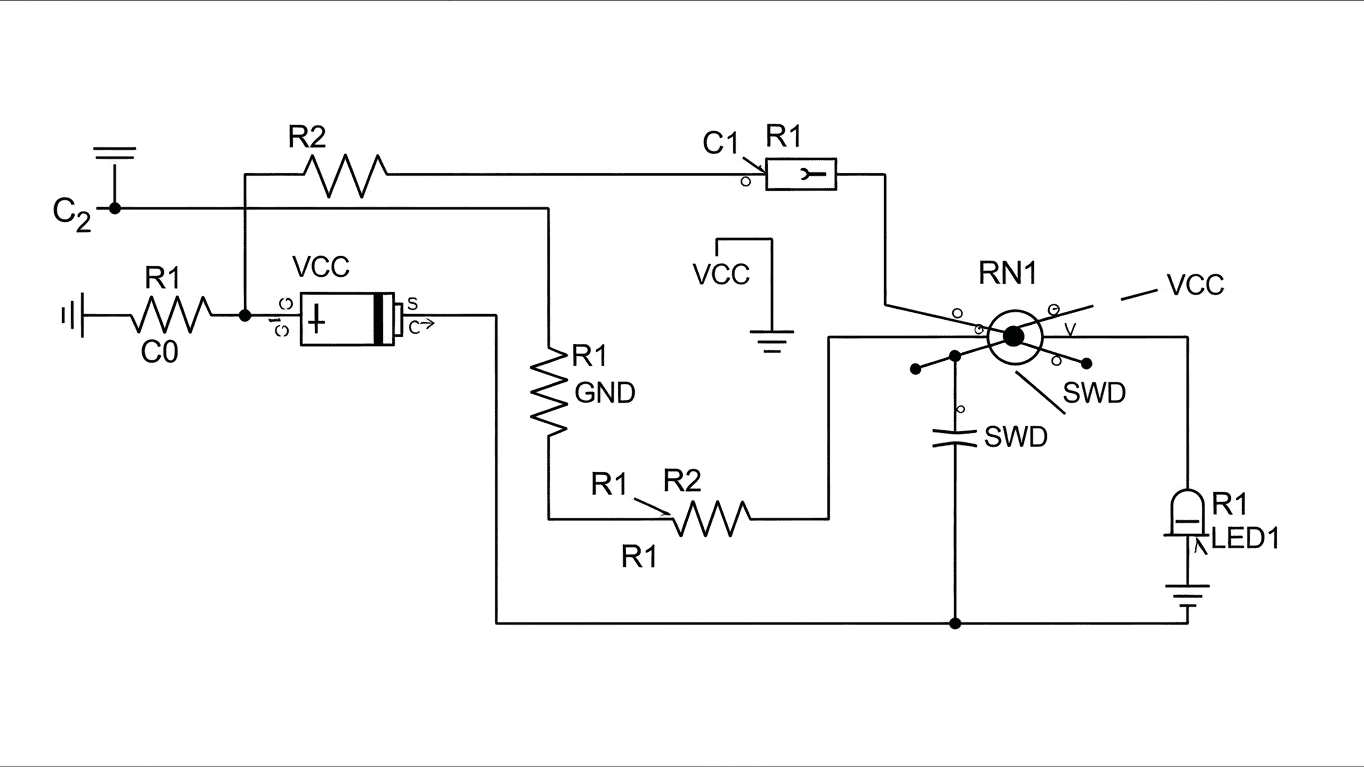

A "Wiring Diagram For 220 Volt Air Compressor" is essentially a schematic that illustrates the electrical pathway of your air compressor. It shows how the power source, typically from a 220-volt outlet, connects to the motor, pressure switch, thermal overload protector, and any other electrical components. This diagram is vital because it simplifies complex electrical systems into an easy-to-follow visual representation. It helps in identifying the purpose of each wire and the correct connections required. For instance, it will clearly label:

- Hot wires (L1 and L2 for 220V)

- Neutral wire (if applicable to specific components)

- Ground wire

- Connections to the motor windings

- Connections to the pressure switch contacts

- Connections to the thermal overload switch

The primary use of a "Wiring Diagram For 220 Volt Air Compressor" is for installation, maintenance, and repair. When installing a new compressor, the diagram ensures you connect the power supply correctly to avoid damaging the unit or causing an electrical short. During maintenance, it can help you trace a circuit or identify a faulty component. For repairs, it's indispensable. A technician can use the diagram to:

- Diagnose electrical issues by following the flow of current.

- Test individual components for continuity and functionality.

- Make replacements or repairs with confidence, ensuring all connections are re-established precisely as they were.

- Identify the correct wire gauge and type required for safe operation.

The importance of correctly interpreting and following a wiring diagram cannot be overstated, as it directly impacts safety, efficiency, and the longevity of your air compressor.

Here’s a simplified breakdown of common components found in a 220-volt air compressor wiring diagram:

| Component | Function |

|---|---|

| Power Cord/Plug | Connects the compressor to the 220V power source. |

| Pressure Switch | Turns the motor on and off based on tank pressure. |

| Thermal Overload Protector | Shuts off the motor if it overheats. |

| Motor Capacitors | Assist in starting and running the motor. |

| Motor Windings | The electrical coils that generate the motor's magnetic field. |

To ensure you have the most accurate and detailed information for your specific model, always refer to the manufacturer's provided "Wiring Diagram For 220 Volt Air Compressor." This document is specifically tailored to your unit and will contain the precise layout and specifications needed.