Understanding the Wiring Diagram Capacitor Start Motor is crucial for anyone working with or troubleshooting these common electric motors. This diagram serves as a roadmap, detailing how the electrical components are connected to ensure the motor starts efficiently and runs as intended. A correctly interpreted Wiring Diagram Capacitor Start Motor can save time, prevent damage, and ensure safety.

The Ins and Outs of a Capacitor Start Motor

A capacitor start motor is a type of single-phase AC induction motor. Its primary advantage lies in its ability to generate a stronger starting torque compared to simpler single-phase motors. This makes them ideal for applications where the motor needs to overcome a significant load at startup, such as in compressors, pumps, and fans. The core of its starting capability comes from an auxiliary winding and a capacitor, which work together to create a phase shift in the current supplied to the auxiliary winding. This phase shift effectively creates a rotating magnetic field, allowing the motor to start rotating with more force.

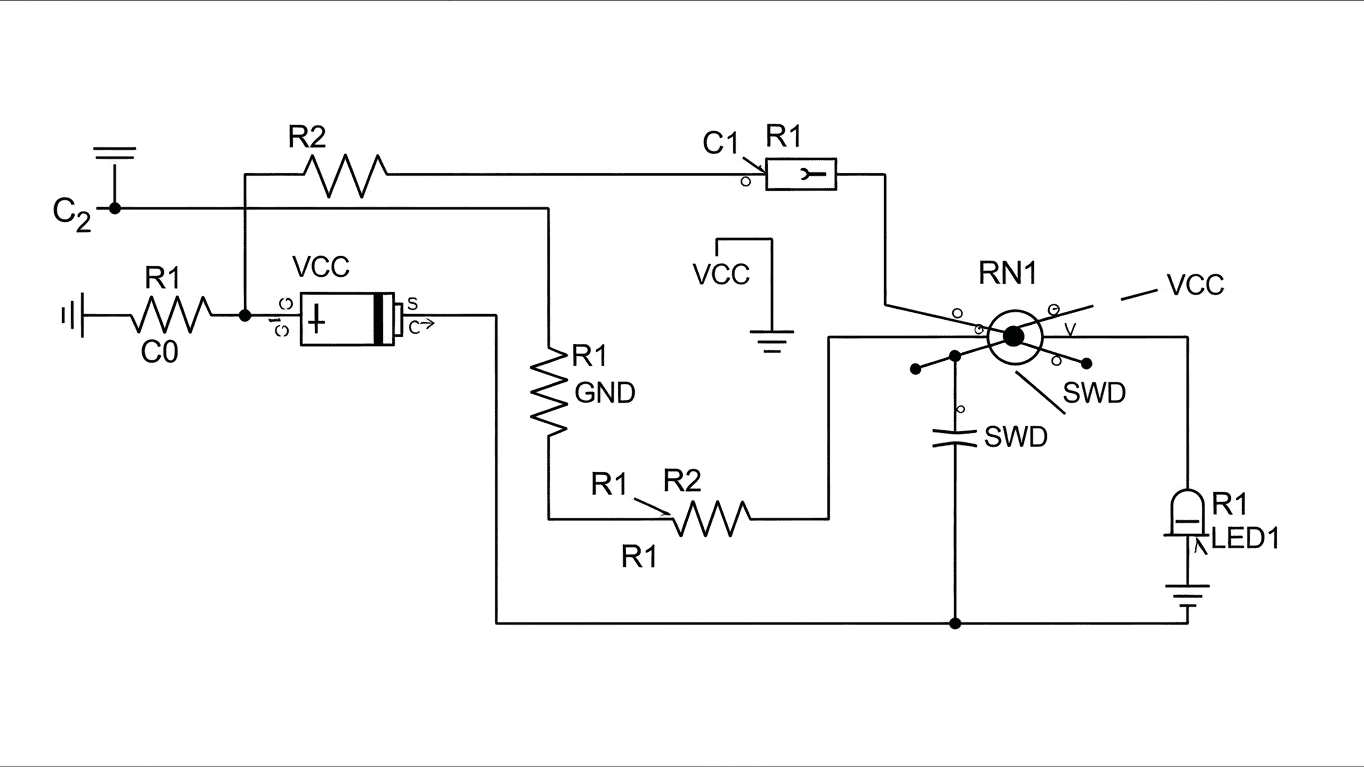

The basic operation involves a main winding and a starting winding. When power is applied, both windings receive current. However, the capacitor, connected in series with the starting winding, causes the current in this winding to lag behind the current in the main winding. This difference in phase is what generates the necessary starting torque. Once the motor reaches a certain speed (typically around 75% of its rated speed), a centrifugal switch or a potential relay disconnects the starting winding and capacitor from the circuit. This is a critical step because if the starting winding and capacitor remain energized at full speed, they can overheat and be damaged. The accurate wiring of this starting mechanism is the most important aspect illustrated by the Wiring Diagram Capacitor Start Motor.

- Main Winding: Provides the primary magnetic field for continuous operation.

- Starting Winding: Creates a temporary magnetic field to initiate rotation.

- Capacitor: Shifts the phase of the current in the starting winding.

- Centrifugal Switch/Potential Relay: Disconnects the starting circuit once the motor is up to speed.

The Wiring Diagram Capacitor Start Motor will clearly show the connections between the power source, the motor windings, the capacitor, and the switching mechanism. It might also detail terminal markings and wire colors, which are essential for correct identification. For example, a typical diagram might show:

| Component | Connection Point |

|---|---|

| Line (L) | Connected to one end of the main winding. |

| Neutral (N) | Connected to the other end of the main winding. |

| Starting Winding | Connected in series with the capacitor and to a separate terminal. |

| Capacitor | Connected between a terminal for the starting winding and another terminal that is also connected to the line or neutral side of the main winding, depending on the specific design. |

| Centrifugal Switch | Located in series with the starting winding and capacitor, typically mounted on the motor shaft. |

To effectively troubleshoot or install a capacitor start motor, referring to its specific Wiring Diagram Capacitor Start Motor is indispensable. This guide will provide the necessary visual information to understand the flow of electricity and the sequence of operations for both starting and running modes.

To further your understanding and successfully work with your motor, please refer to the detailed schematic found in the documentation provided with your specific motor model.